produce of stone crusher

Aggregate Production Optimization in a Stone-Crushing

2020年2月8日 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone. The L18 orthogonal array has been used to investigate how the CSS, throw, eccentric speed, and particle

Crusher, Crushing plant All industrial manufacturers

jaw crusher BR380JG-3. mobile. Capacity: 50 t/h 240 t/h. Motor power: 159 kW. Opening height: 1,065 mm. Eco-friendly performance moving to a new stage. The operating

(PDF) Design of Impact stone crusher machine

2019年5月31日 The main objective is to design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure to

Stone Crusher ConeJaw Crushers Machine

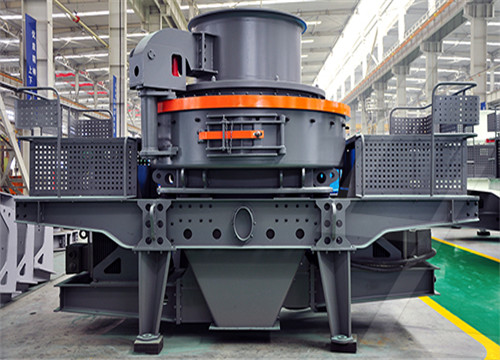

Classification of Stone CrusherMining Rock Crusher MachineHow to Choose An Optimal Stone CrusherHow to Maximize The Crusher Efficiency, Longevity

According to the crushing force mode, the crusher machine divides into stone crushers and grinding machine. What’s the difference between stone crusher and grinding mill? General speaking, the former one is used to reduce the larger slab into a smaller size, various models of crusher are designed to maximize producti在jxscmine上查看更多信息

Stone Crushing Machine Stone Crushers

2023年3月3日 Mobile stone crushing plant is a crusher plant built on a portable body. Unlike the stationary crusher plant, the mobile crusher plant can be easily transported from one area to another. It has a lower

Stone Crushing Plant Automatic Stone Crusher

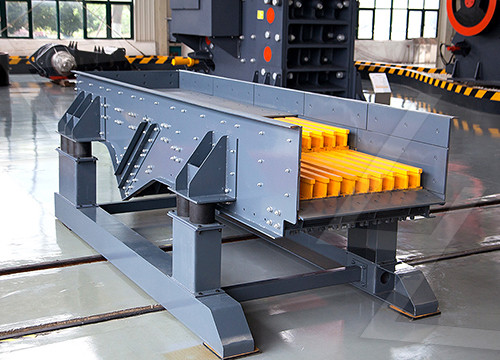

The stone crushing plant manufactured by AGICO mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor,centralized electronic control system, and other equipment.

10 Types of Stone Crusher Plants Price and More for Sale

2 之 The stone crusher plant is used for producing sand, rock and stone for construction, highway, railway and other applications. Fote Heavy Machinery, with 40

Crushing Plant Design and Layout

1 Considerations of stone crusher plant design. The basic purpose of crushing ore is to achieve a certain particle size requirement for ore, raw materials or fuel. In ore dressing, the purpose of crushing ore is: (1)

Should know all about Stone Crusher Plant

Stone Crusher plant Capacity. The stone crusher plant will available from 50 TPH to 600 TPH (ton per hour). The plant can produce the 8 variants of material. Just to get the different variant material you also need to put the

Working Process Of Stone Crushing Process

As we’ve said, Aimix’s stone crushing process line(jaw crusher, cone crusher, vibrating screen, belt conveyor) was exported to Sri Lanka in August 2017. Here, I will introduce its working process to all of you. As a

Aggregate Production Optimization in a Stone-Crushing

2020年2月8日 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone. The L18 orthogonal array has been used to investigate how the CSS, throw, eccentric speed, and particle size affect the products of the cone of the crusher (its cumulative weight fraction). The CSS,

Crusher, Crushing plant All industrial manufacturers

jaw crusher BR380JG-3. mobile. Capacity: 50 t/h 240 t/h. Motor power: 159 kW. Opening height: 1,065 mm. Eco-friendly performance moving to a new stage. The operating weight of the BR380JG-3 ranges from 33,500 to 35,310 kg, with a

Design of a small-scale granite stone crusher ScienceDirect

2020年1月1日 The small scale granite stone crusher was designed to crush stones of approximately 25-135mm to about 24-20.2mm in size. SOLID WORKS was used as a stress analysis tool on the gear (main crushing part) to determine the regions where the gear experiences maximum force according to Von-Misses failure criteria. It was observed the

Stone Crusher Professional Manufacturer And

Technical Characteristics of Best Stone Crusher Plant: As a professional crusher exporter, Aimix’s stone crusher design has many excellent features compared with ordinary crusher. The limestone grinding machine not

Stone crusher plant details Henan Deya Machinery Co., Ltd.

2022年4月27日 Stone crusher plant details, from A to Z. 1. Background. In recent years, with the development of capital construction around the world, the demand for sand and gravel materials is increasing day by day. In the background of the restriction of river sand mining and the shortage of sand, many places encourage and support the investment for

The 10 Best Mobile Crusher Manufacturers Globally

2 之 Mobile stone crushers are usually classified as primary, secondary, and tertiary. There are different machines in each category, from gyrator crushers to hammer crushers to jaw crushers. Typically, the maximum feed size is 1500 mm, and the maximum production capacity of a portable crusher is 500 t/h.

Crushing Plant Design and Layout

1 Considerations of stone crusher plant design. The basic purpose of crushing ore is to achieve a certain particle size requirement for ore, raw materials or fuel. In ore dressing, the purpose of crushing ore is: (1)

Mobile Crusher Eastman Rock Crusher

Production capacity: 70-130t / h Feeding granularity: ≤500mm The discharge can meet the requirements: 10-30mm; Option 3. Small stone fine crushing ($600,000 -100,000) Main crushing machine: 1200 * 1200 fine

Gravel Crushers Mobile Impact Crushers RUBBLE MASTER

Crusher run gravel is typically used for driveways and ub-bases, or it is refined further with a screening plant to produce base (surface) materials or clear stone products. RUBLE MASTER's line of mobile impact crushers produce crusher run material up to 3"-. The top size varies greatly if not controlled by a screening plant.

Jaw Crushers Korea Jaw Crusher Manufacturer Single

JAW CRUSHER. Jaw Crusher is a kind of Stone crusher, and jaw crusher is also called Rock crusher. Sand plant is the ideal equipment for sand making and building stones reshaping. Sand Plant produce the crushed sand as an alternative of river sand.You can find out Samyoung Full Sand Plant List.

China Stone Crusher, Stone Crusher Manufacturers,

China Stone Crusher manufacturers Select 2023 high quality Stone Crusher products in best price from certified Chinese Construction Machine, Mining Equipment suppliers, wholesalers and factory on Made-in-China Small Stone Jaw Crusher Crusher for Calcium Carbonate Gypsum Limestone Quartz Graphite Calcite Feldspar Fluorite Powder

Stone Crushing Equipment Market Analysis Report 2027

It is categorized into various types such as jaw crusher, impact crusher, cone crusher, gyratory crushers and others. It is widely used in mining and construction sectors. COVID-19 pandemic has shut-down the production of various products in the stone crushing equipment's, mainly owing to the prolonged lockdown in major global countries

Stone Crusher Professional Manufacturer And

Technical Characteristics of Best Stone Crusher Plant: As a professional crusher exporter, Aimix’s stone crusher design has many excellent features compared with ordinary crusher. The limestone grinding machine not

Stone Crushing Machine Stone Crushers

2023年3月3日 Mobile stone crushing plant is a crusher plant built on a portable body. Unlike the stationary crusher plant, the mobile crusher plant can be easily transported from one area to another. It has a lower

AggregateRock Crushing Equipment Stedman

Primary crushers are first in a typical size reduction operation. Primaries like our Mega-Slam™ horizontal shaft impactor are commonly used in the aggregates industry to handle large feed sizes. The Grand-Slam™ HSI is well suited as secondary crusher for aggregate production for a wide range of materials including limestone, frac sand, gravel, stone,

The 10 Best Mobile Crusher Manufacturers Globally

2 之 Mobile stone crushers are usually classified as primary, secondary, and tertiary. There are different machines in each category, from gyrator crushers to hammer crushers to jaw crushers. Typically, the maximum feed size is 1500 mm, and the maximum production capacity of a portable crusher is 500 t/h.

Stone Crushing MetallurgistMineral

2020年10月20日 One very successful type of crusher for use in production of stone sand is the rod mill, using wet-grinding methods and employing a feed of not over one inch in size. In many cases the screenings resulting

(PDF) AGGREGATE CRUSHING PLANT Birhanu Shiferaw

TJPRC Publication. The purpose of this study is to know the effects of coarse aggregate on the properties of concrete with the change in age of crusher screen. Location selected for the study purpose has been limited to Durg district of Chhattisgarh region. Two numbers of quarries have been selected having lime stone as a major source.

Experimental optimisation of crushing parameters in stone

2023年4月6日 Download Citation On Apr 6, 2023, Shubhangi P. Gurway and others published Experimental optimisation of crushing parameters in stone crusher using taguchi method Find, read and cite all the

Jaw Crushers Korea Jaw Crusher Manufacturer Single

JAW CRUSHER. Jaw Crusher is a kind of Stone crusher, and jaw crusher is also called Rock crusher. Sand plant is the ideal equipment for sand making and building stones reshaping. Sand Plant produce the crushed sand as an alternative of river sand.You can find out Samyoung Full Sand Plant List.